VESTENAMER®

The world's most versatile rubber additive

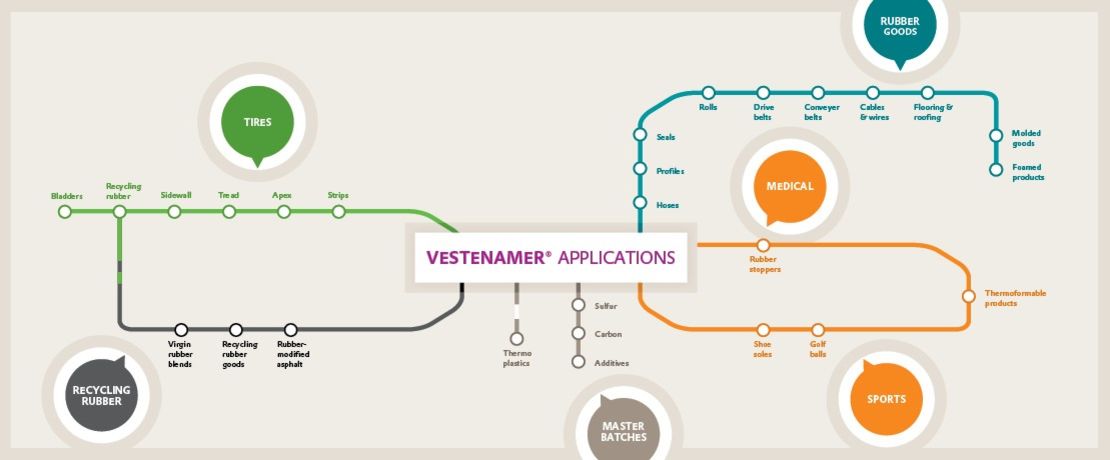

VESTENAMER® has been used as an additive in the rubber industry for years. By virtue of its properties, the versatile trans-polyoctenamer can solve a variety of problems in the compounding and processing of rubber. It can also improve the dynamic properties of the vulcanized material and as well be used to recycle waste rubber.

VESTENAMER® is a semicrystalline polyolefine additive that is also described as a trans-polyoctenamer rubber (TOR) since it is based on cyclooctene and shows a high proportion on trans-double bonds. As a polymeric processing aid, it acts as a plasticizer of rubber compounds in the mixing and manufacturing process. Due to the presence of double bonds, VESTENAMER® takes part in the vulcanization process and is incorporated into the rubber matrix. Therefore, one can consider VESTENAMER as a reactive plasticizer.

The properties of VESTENAMER®:

- low melting point

- low viscosity in the melt (Mooney <10)

- high crystallinity, fast recrystallization rate

- high percentage of macrocycles (>30 %)

- a double bond every eighth carbon Atom

- high proportion of trans-configured double bonds

Low viscosity above the melting point

VESTENAMER® has a high macrocycle content that significantly reduces its molecular weight. Unlike linear macromolecules, macrocycles can crosslink to a completely three-dimensional network, even at low molecular weight. Combined with a broad molecular weight distribution, its low molecular weight is also responsible for its unusually low viscosity at temperatures above the melting range. At 100 °C VESTENAMER® shows a Mooney viscosity ofless than 10 units.